Aluminum metallized film

Key words:

Biaxially Oriented Polypropylene Film | Metallized Film | Lithium Battery Separator

Classification:

Description

| Products | Classification | Product Description |

| Metallized film | Metallized capacitor film | Metallized film is a value-added product for evaporated capacitor film, where the metal layer deposited onto the surface of the film becomes an electrode. The electrode for aluminum metallized capacitor film is made of aluminum, with an extremely thin electrode layer (in the nanometer range), exhibiting excellent conductivity and strong oxidation resistance. This product is used for electrodes and dielectric materials of various metallized self-healing film capacitors, and has been widely applied in low-voltage power, household appliances, and some DC capacitors. Zinc-aluminum composite metallized capacitor film is produced through the deposition of a very thin layer of zinc-aluminum composite metal material on the surface of metallized capacitor film as the electrode. While its oxidation resistance is inferior to that of aluminum metallized capacitor film, it exhibits smaller capacity decay and better self-healing properties. This product has been extensively applied in various fields such as medium and low-voltage power, household appliances, energy-saving lighting, automotive electronics, and communication equipment. |

Product Description

1. Advantages

(1) Superior conductivity compared with aluminum-zinc films;

(2) Excellent self-healing properties;

(3) Strong resistance to atmospheric corrosion, convenient storage with a long shelf life.

2. Disadvantages

(1) Larger capacity decay compared with aluminum-zinc film;

(2) Difficulty in metal spraying onto the coating;

(3) Increased resistivity due to oxidized aluminum during metal spraying.

■ Applications: Capacitors of power, refrigerator, air conditioners, and other devices

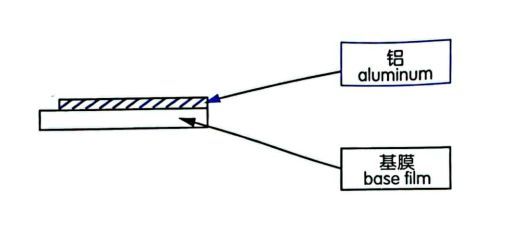

Structure

Specifications and dimensions

| Item | Unit | Nominal value | |

| Disk diameter | mm | Inner diameter | 75 |

| Outer diameter | 150-300(Customizable ) | ||

| Thickness | μm | 5、6、7、8、9、10、12 | |

| Width * Margin allowance | mm | 25*1.5 35*1.5 15*2 15*2.5 19*1.5 | |

| 20*1 15*2.5 15*2.5 | |||

| 30*1.5 18*1.5 28*1.5 20*1.5 23*1.5 60*5 12*1 | |||

| 15*1 25*1 30*1 12*1.5 10*2.5 15*2.5 20*2.5 25*2.5 | |||

| 30*2.5 35*2.5 37.5*2.5 40*2.5 45*25 | |||

| 50*2.5 55*2.5 60*2.5 65*2.5 65*2.5 70*2.5 | |||

| 75*2.5 80*2.5 85*2.5 90*2.5 95*2.5 | |||

| 100*2.5 115*2.5 120*2.5 | |||

Related Products

Your inquiries are expected.

If you are interested in our products, please leave your information, and we will get in touch with you as soon as possible. Thank you!