Aluminum-zinc Metallized Film

Key words:

Biaxially Oriented Polypropylene Film | Metallized Film | Lithium Battery Separator

Classification:

Description

Product Description

Features

1. Advantages

(1) Minimal capacity decay over extended usage;

(2) Easier metal spraying thanks to the thick coating compared with aluminum films;

(3) Low resistivity due to zinc oxide during metal spraying.

2. Disadvantages

Poor resistance to atmospheric corrosion, limiting long-term storage capabilities.

Applications: Capacitors of power, refrigerator, air conditioners, and other devices

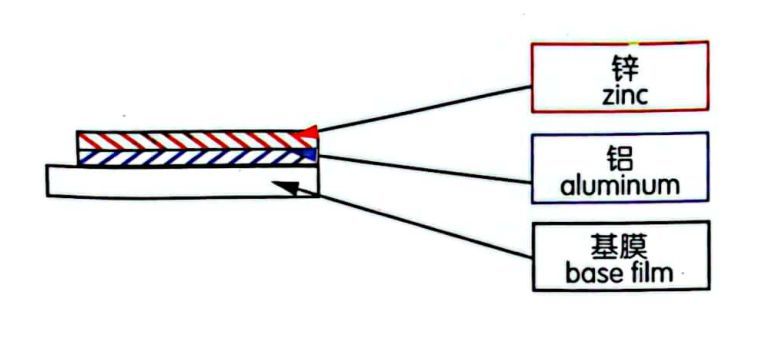

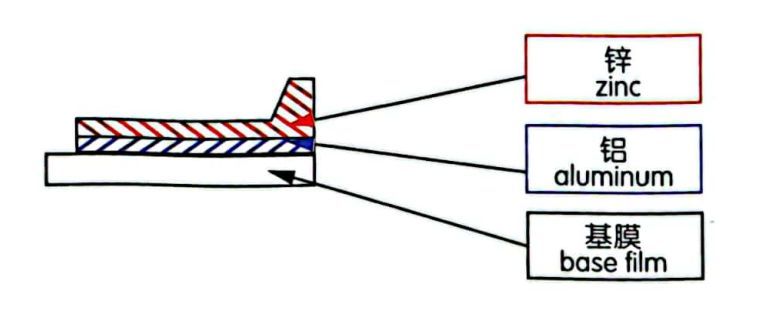

Structure

1. Non-thickened aluminum-zinc film edges

2. Thickened aluminum-zinc film edges

Specifications and dimensions

| Item | Unit | Nominal value | |

| Disk diameter | mm | Inner diameter | 75 |

| Outer diameter | 150-300(Customizable ) | ||

| Thickness | μm | 5、6、7、8、9、10、12 | |

| Width * Margin allowance | mm*mm | 4、5、6、7、8、9、10、12 | |

| 14*2 14*1.5 21×2 26*2.5 17.5*1.5 19*1.5 | |||

| 30*2.5 35×2.5 37.5*2.5 40*2.5 45*2.5 | |||

| 50*2.5 55*2.5 60*2.5 65×2.5 70*2.5 | |||

| 75*2.5 80*2.5 85*2.5 90*2.5 95*2.5 | |||

| 100*2.5 115*2.5 120*2.5 125*2.5 130*2.5 | |||

Test standard: GB/T 13542.2-2009

| Environmental testing conditions | Unless otherwise specified, all items should be tested under the conditions of 23 ± 2℃, 50 ± 5% relative humidity, and air cleanliness of Class 10,000. |

| Sampling | Before sampling, remove at least three layers from the film roll to be tested, and then take samples according to the specified quantity. |

| Visual inspection | Check the appearance under illumination exceeding 500 lx. |

| Thickness measurement | Test in accordance with Article 4 of GB/T 13542.2. 。 |

| Measurement of tensile strength and elongation at break | Test in accordance with Article 11 of GB/T 13542.2 at a stretching velocity of (100 ± 20) mm/min, a clamping interval of (100 ± 20) mm, and a sample width of (15 ± 1.0) mm. |

| Thermal shrinkage measurement | Test in accordance with Article 23 of GB/T 13542.2 at a smokebox temperature of 120 ± 2℃ and a baking duration of 10 min. |

| Tension measurement in wet conditions | Test in accordance with Article 10 of GB/T 13542.2. |

| Surface roughness measurement | Test in accordance with Article 8 of GB/T 12542.2. |

| Void content measurement | Test in accordance with Article 35 of GB/T 13542.2. |

| Dielectric strength measurement | Implement the DC test component method in accordance with Article 18.2.1 of GB/T 13542.2, and the 50-point electrode method Article 18.2.2 of GB/T 13542.2. |

| Volume resistivity measurement | Test in accordance with Article 16 of GB/T 13542.2. |

| Surface resistivity measurement | Test in accordance with Article 15 of GB/T 13542.2. |

| Electric strength measurement | Test in accordance with Articles 19.3 and 19.1 of GB/T 13542.2 at a test voltage of 200 V/μm with the tested area not less than 5 m2. |

| Curling test | Test in accordance with Article 7.3 of GB/T 13542.2. |

| Melting point determination | Test in accordance with Article 2.2 of GB/T 13542.2. |

| Density measurement | Test in accordance with Article 5 of GB/T 13542.2. |

Related Products

Your inquiries are expected.

If you are interested in our products, please leave your information, and we will get in touch with you as soon as possible. Thank you!